Description

Industrial coolers and cooling pads are components used in various industrial settings to regulate and manage temperature levels, especially in systems where cooling is crucial for maintaining operational efficiency and safety. Here’s a breakdown of each:

- Industrial Cooler: Industrial coolers are devices or systems designed to remove heat from a specific environment or equipment. These coolers come in various forms, including air coolers, water coolers, or refrigeration systems, depending on the specific application and cooling requirements of the industrial setting. They operate by transferring heat away from the targeted area, thereby reducing the temperature and maintaining a suitable working environment for machinery, processes, or products.

- Air Coolers: These utilize air as the cooling medium and can involve various methods such as fans, evaporative cooling, or air conditioning systems to remove heat from the surroundings.

- Water Coolers: Water-based cooling systems involve the circulation of water to absorb heat from the equipment or process, subsequently dissipating it elsewhere to maintain a lower temperature.

- Refrigeration Systems: These systems use refrigerants to absorb heat from a space and then reject it to the surrounding environment, effectively lowering the temperature within the industrial setting.

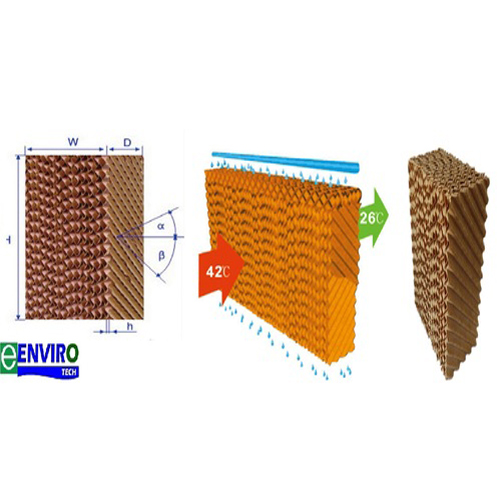

- Cooling Pads: Cooling pads are specifically designed components used in certain cooling systems, such as in evaporative air coolers or air conditioning units. These pads are typically made of materials that allow water to pass through them easily, promoting evaporation. When air is passed through or over these wet pads, the heat from the air is absorbed, resulting in a cooler air output. Cooling pads are commonly employed in areas with dry climates or where efficient, cost-effective cooling solutions are required.

In combination, industrial coolers and cooling pads play pivotal roles in maintaining optimal temperatures within industrial environments. They help to prevent overheating of machinery, regulate processes that require specific temperature ranges, and create comfortable working conditions for employees in factories or manufacturing plants. These components contribute significantly to the efficiency, productivity, and safety of various industrial operations.